Anatomy of a Bad Bell Striker Repair

Anatomy of a Bad Bell Striker Repair

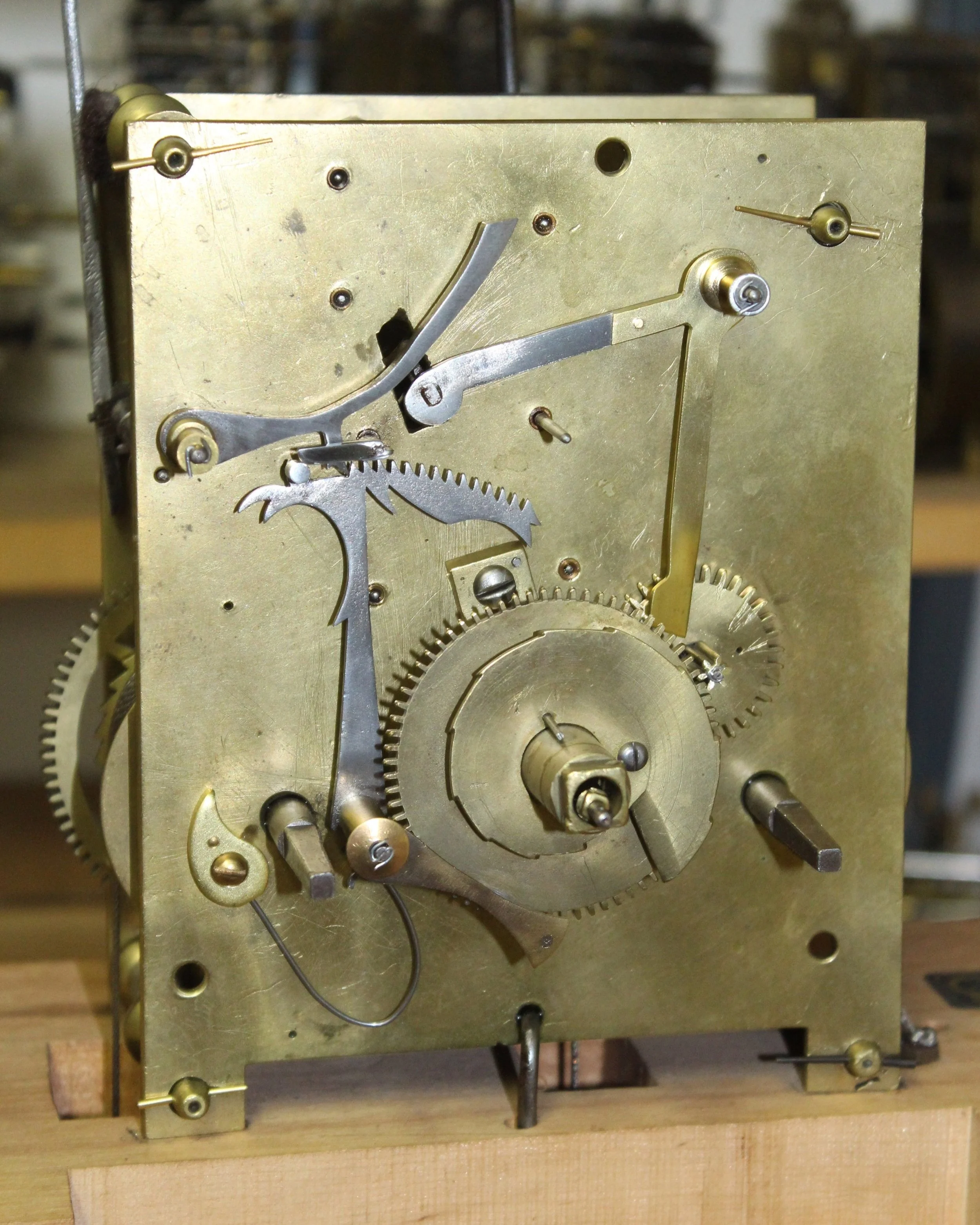

The clock movement shown below is what we call an antique bell striker. These movements were found in tall clock cases, were made one at a time by hand and were quite durable. However, because they are very old, likely 170 years or more, they have often been the victims of bad repair work over the long span of their lives. The repairs we will catalog below, would not be as egregious as they are except that this clock has been “overhauled” by a respected clock shop based here in Ohio. I do not believe that all of the bad repairs were done by the person who performed the “overhaul”, but at the least, these bad repairs were ignored. Some of the ignored bad repairs could have easily been rectified with little cost to the clock owner. Of course, on top of all this, the clock would not work correctly.

I will explain each of these errors below and show how they were repaired properly. It is important to understand that our job here was not to rebuild the entire clock but to correct only those issues that were causing the clock to function improperly and clean up some of the easy errors and blemishes that could be accomplished at low cost.

A. Taper Pins - This is a bit of a nit-pick but tapers pins are not expensive. There should be no need to bend them over if you have the correct size. In my “after” photo I have taper pins that fit the hole without bending. When the repair is complete, I will mark the taper pins for proper length, remove them, cut them to my mark, then sand the ends flat for neatness and reinsert them.

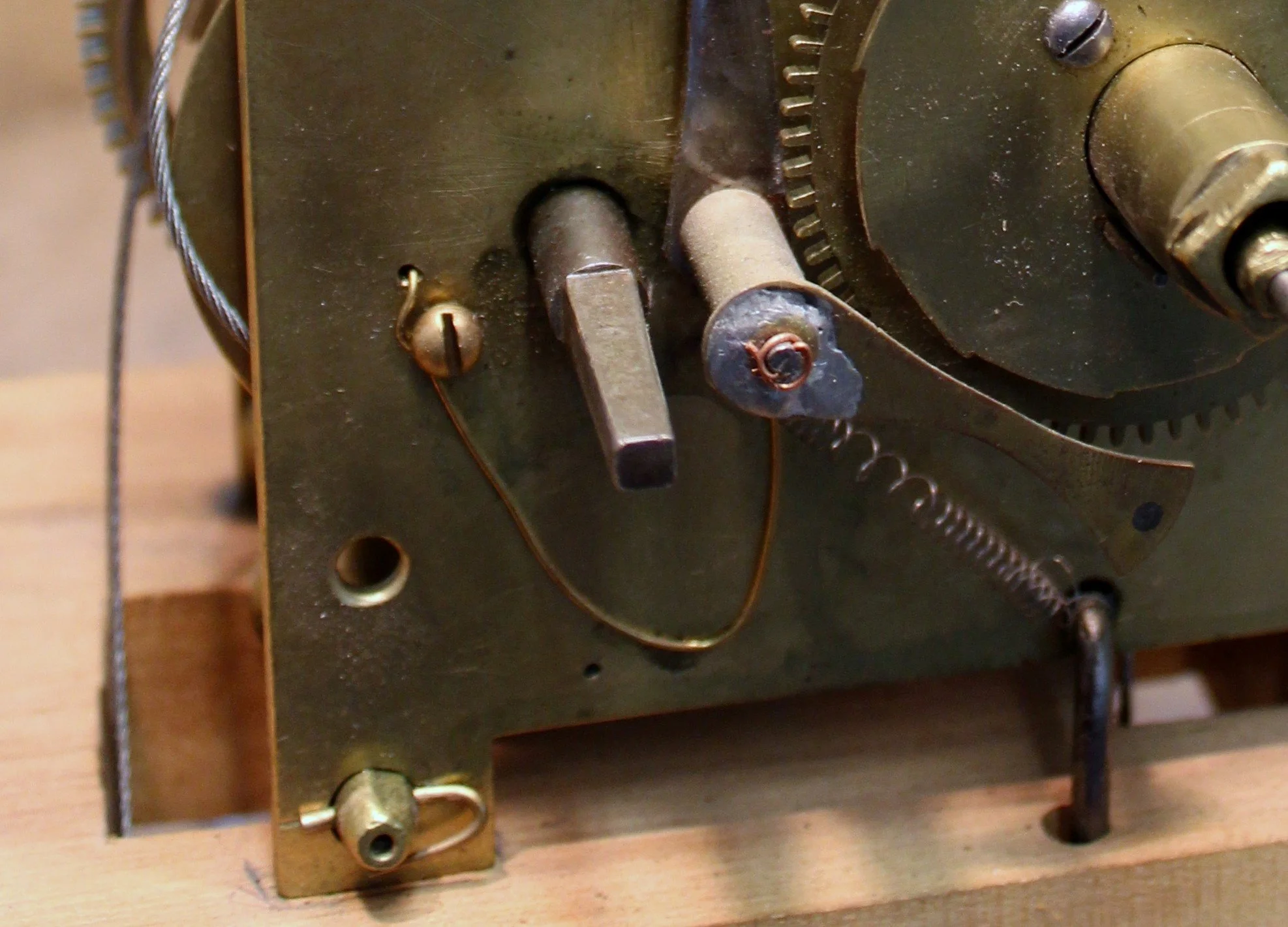

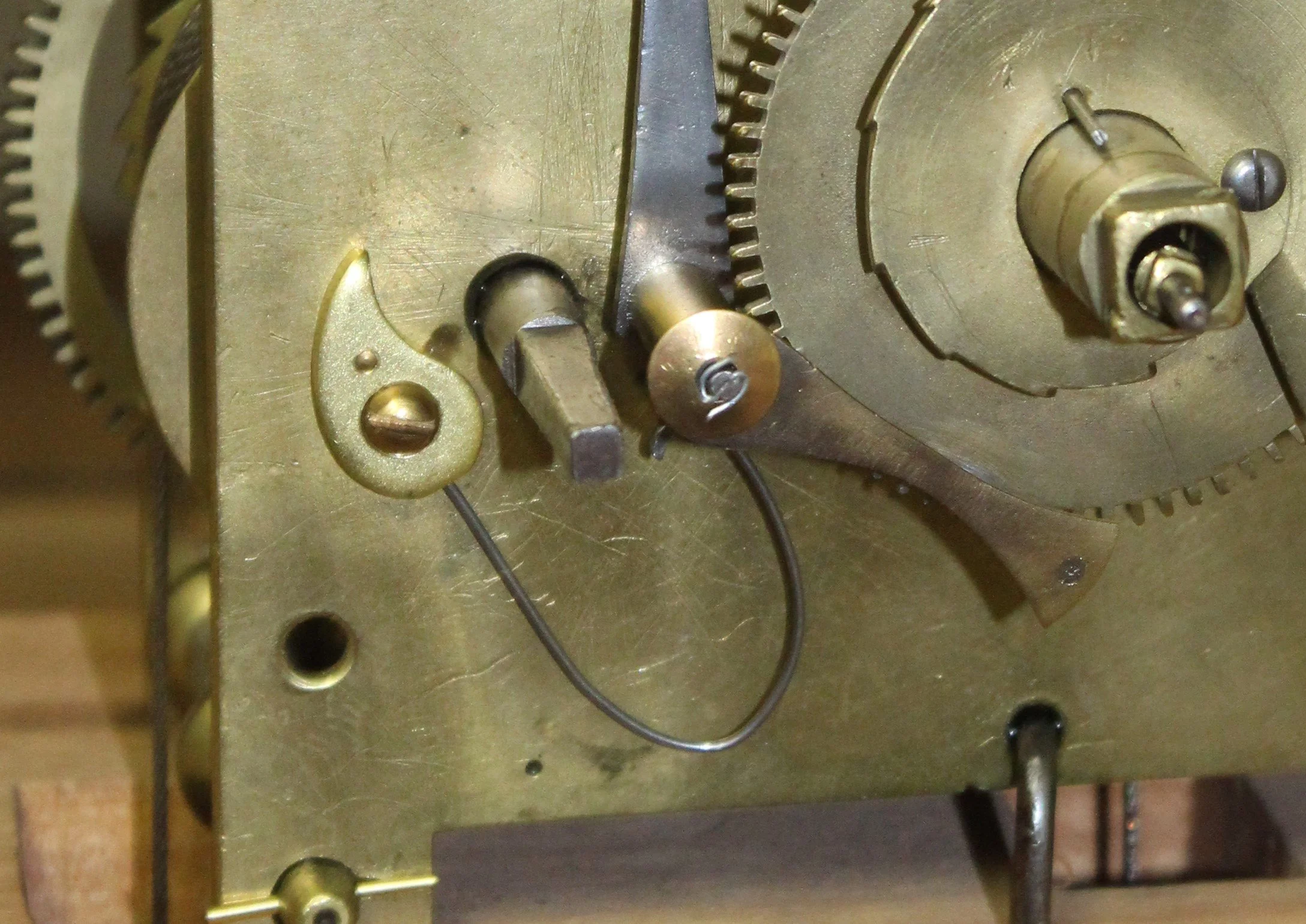

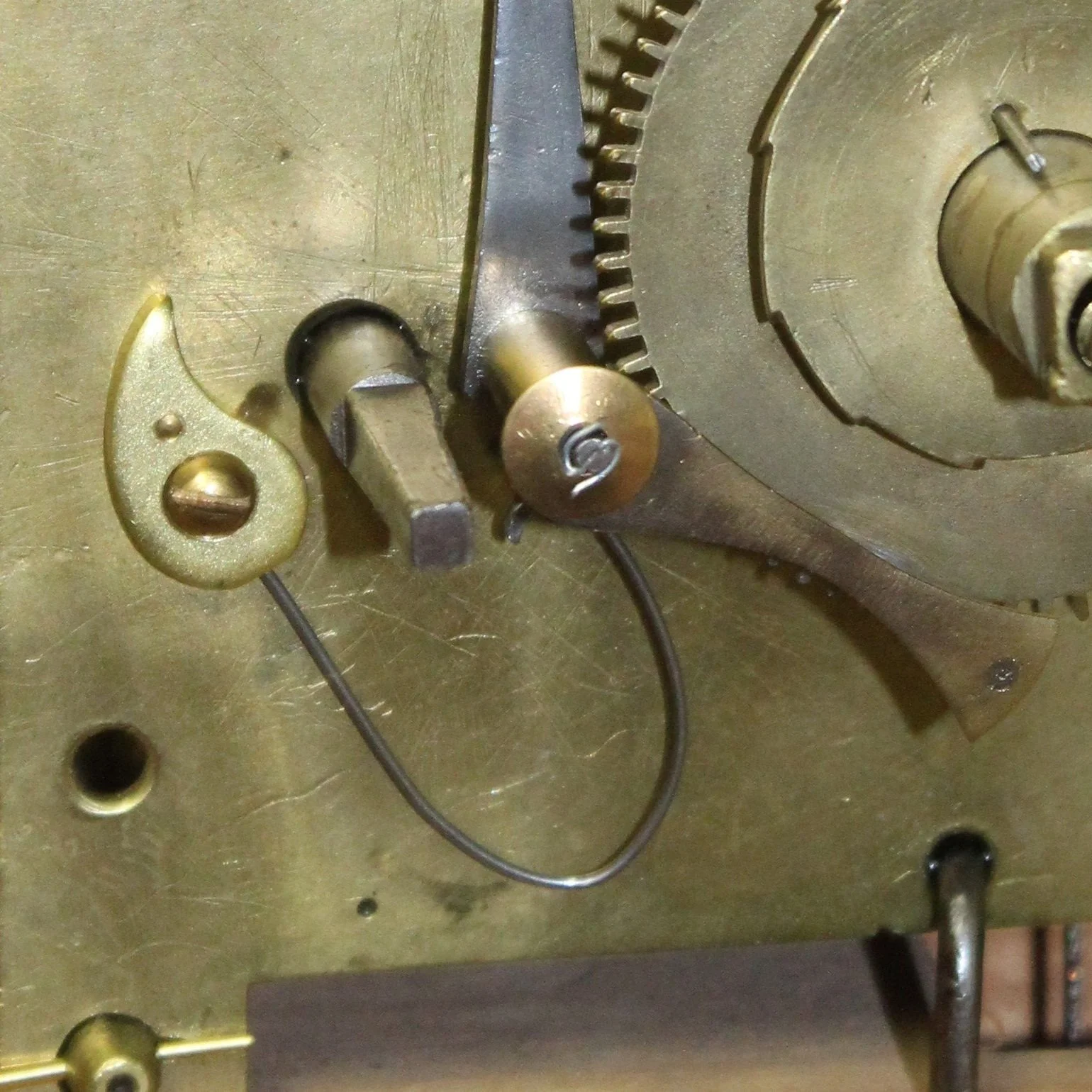

B. Unnecessary Wire Spring - This spring was installed to pull the hammer forward to strike the bell. However, the original spring designed to do this is already present. Here is a photo from the side giving us a better view. The flat hammer spring is below the hammer on the inside of the rear plate (left side). If there were not adequate tension on the original it is easily removed from the outside of the rear plate, adjusted and reinstalled.

c. Soldered on Nut - I can only assume the nut was soldered on to add weight to the end of the lever to help it fall properly after being lifted to make the clock strike. This lever should not need a weight. If there was a need to add weight to this lever, that means there was something else wrong that was ignored.

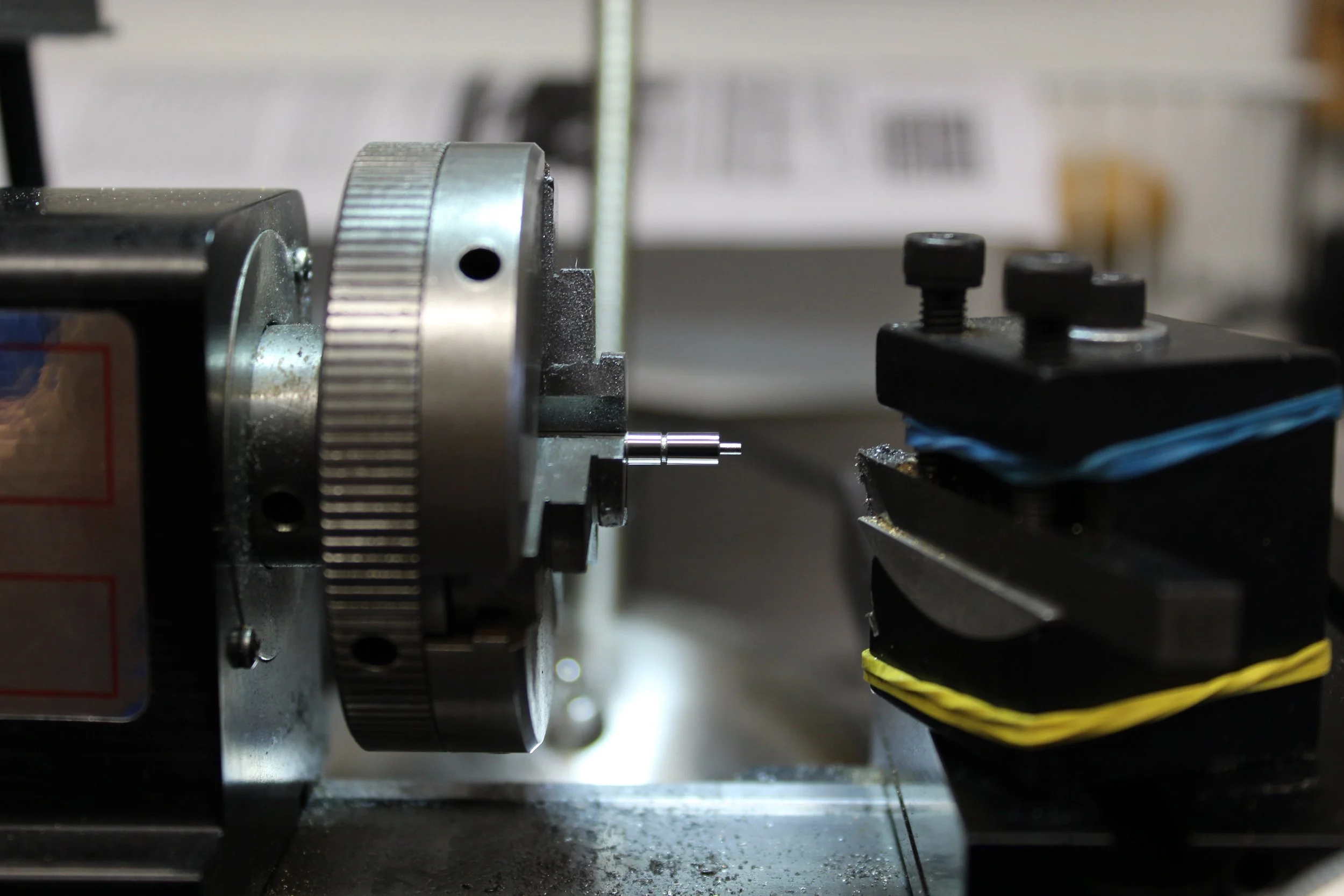

D. Bad Rack Pin - The original pin, designed to stop the strike has been highly modified. It appears that a pin of the wrong diameter was installed and then made larger with the addition of two brass bushings, which have been poorly soldered on over top. The photo just below shows a new pin being made on the lathe. The next photo shows the rack as we found it and the third photo shows the rusty steel rack polished up and the blob of solder holding the brass rack tail to the larger steel rack cleaned up.

Strike rack with bad stop pin

Strike rack with new steel stop pin

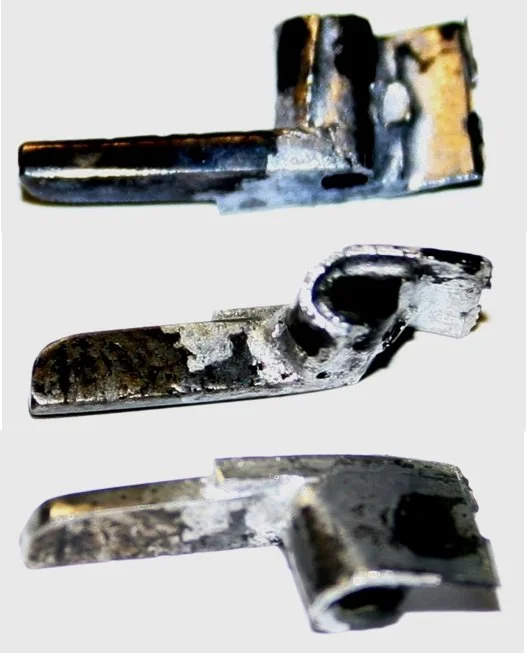

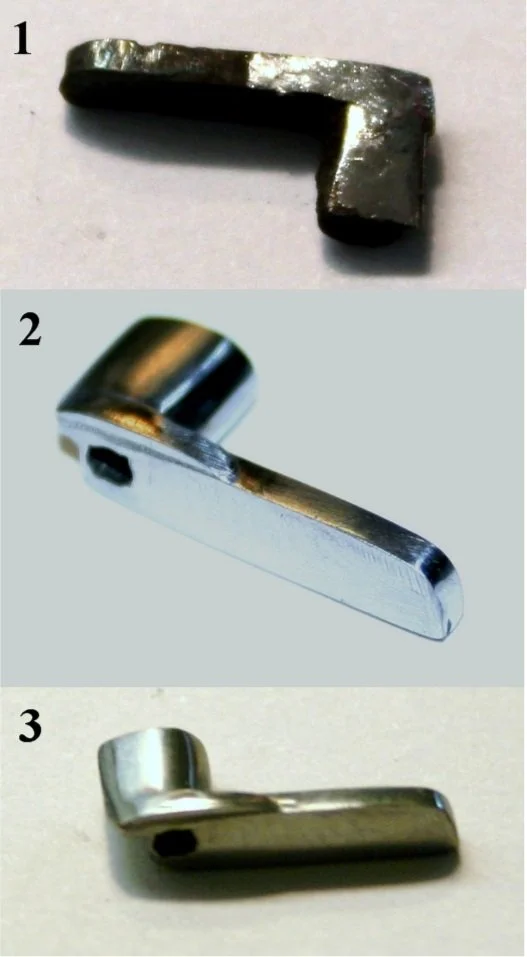

E. Poorly Repaired Gathering Pallet - The gathering pallet is designed to “gather” one tooth of the rack for each strike that occurs on the hour. after it has counted the appropriate number of strikes the tail of the gathering pallet hits the stop pin on the rack and stops the strike. After performing this task for more than a hundred and fifty years or more, this parts will get damaged, worn or break. This one was certainly damaged, but poorly repaired. It was even soldered onto the arbor without cleaning the flux off, causing the surrounding area to rust. Various bits of new metal were soldered onto the original to make it functional. One piece was made of brass which would wear very quickly. The first photo shows the rusted, soldered-on pallet. These typically do not need solder to hold them in place if they are fit properly. Second photo shows close ups of the poor workmanship. The third photo shows the progress on the repair. All the added-on pieces of metal have been removed. New steel was added where necessary to make it functional. It is hard to make a silk purse out of a sow’s ear, but we did the best we could to save to original pallet.

Bad solder job showing rust

Views of poor pallet repair

Cleaned up pallet

F. Solder Blob on Rack - Sometimes solder is necessary, sometimes it is not. If it is necessary, there is a way to do it neatly. You do this by cleaning the area thoroughly, adding a bit of flux, a small amount of solder and with the proper amount of heat applied, the solder will lay down smooth and shiny. Any excess solder can be filed off and the flux removed to prevent the area from rusting. See the strike rack photos above for “D”.

G. Poorly Rigged Rack Spring - This spring is designed to throw the rack down against the snail to prepare it to strike. Reproductions of these springs can be cheaply purchased that will look more professional and less like a rig job. In the middle of the solder, you can see an excessively wrapped piece of copper wire. The photo on the left, below shows the “repair” as we received it. The one on the right shows the reproduction spring in place, the excess solder removed from the rack, a washer placed on top to remove excess play and a proper amount of mild steel wire used to attach the rack to its post. The unnecessary coiled spring has also been removed.

Before

After

H. Badly Repaired Lift/warning Lever - This is the lever that trips the strike function. The lever is rusty and poorly repaired with a nut soldered on as mentioned in “C” above. The nut was removed, the solder cleaned off and a new brass lifting tail was made to replace the poorly repaired one. See before and after photos below.

Before

After

I Shims - There is nothing wrong with using a shim, when necessary, but there is also no need to leave the shims protruding out from behind the part you are shimming. We resized the shims and tucked them under the bridge plate where they would not be visible. In these close ups, you can also see that bronze bushings were used to rebuild the worn bearing surfaces on this clock when hard brass should have been used instead. The bronze bushings were functional, just not appropriate for a clock of this age. Those bronze bushings are still in place after my work was completed because I was only repairing the outside of the clock. You can understand that the owner of this clock had already spent a considerable amount of money having the previous work done. Since the bronze bushings were functional, he asked me to leave well enough alone so he would not have to pay me to restore the entire clock. You can also see that rust has been buffed off the rack and the screw.

J. Black Marks - Clockmakers sometimes will make an alignment mark on a clock part, but when they do, they remove the marks when the work is done. In the photos below, long before the black marks were made you can also see someone made large scratches on the minute wheel in the center of photo.

K. Busted Out Minute wheel post-This is something we see quite frequently. In the photo on left, in the center of the wheel at the center of photo, you can see a jagged edge. The steel post that goes through the minute wheel used to be longer. It had a hole in it, in which a taper pin or wire would go to keep the wheel from coming off the post. If too much pressure is applied here, the tip will break off. Fortunately, there was enough pinion height, that we could file a bit off the top, expose some more of the steel post and drill a new hole in which to insert a wire to hold it on.

L. Poorly Repaired Tooth - In the center of the photo at below left, you can see some solder where a tooth has been repaired. Once again there has been an excessive use of solder with little effort made to clean up the area. It is unfortunate that I do not have a good “after” photo of this area. when I took the larger version of the cropped photo at below right, I had the snail (where the tooth was repaired) in a position where it is blocked by the rack tail in a way that does not allow you to see this area after I cleaned it up.

M. Hand Shaft Off Center - The photo below right, in the lower left corner, clearly shows the tip of the hand shaft appearing low in the circular opening of the hour pipe. This usually indicates that the bushing installed in the rear plate has been drifted out of position. If the hand shaft bushing was installed a bit high on the rear, the hand shaft would appear a bit low in the front, which it does. Once again, I was not being paid to rebuild the entire clock movement, so this area was not something I repaired. Fortunately, for the owner, it was not causing an issue with the running of the clock.

N. Unnecessary Spring - As previously discussed, the coiled steel spring you see in this photo below is unnecessary, as it is doing the same job as the poorly made “U” shaped brass spring. This coiled spring was removed after replacing the brass spring with a more appropriate one.

Before

After

Now we can look at a before and after photo of the entire clock movement

The after picture was taken before I cut the taper pins to size and dressed their ends.

Before

After

In Summary

What we have tried to show here is that even clock shops that have been in business for decades, can produce low quality overhaul work. Unfortunately, you will not always know the quality of the repair work until it is too late. I will admit that not all of our work is our best. Why, might you ask? because not all of our customers are willing to pay for our best work. If they want to risk their money paying us to see if we can get a clock working without performing a complete repair, that is fine, but it is their risk! They know what they are paying for and that there will be no guarantee. However, when a customer pays us to overhaul a clock movement, we absolutely are going to give them our very best work. In the example of the poorly repaired movement discussed above this is not what happened. The clock owner was sold an overhaul and all they received was the clock cleaned and the bearing surfaces repaired but most everything else was ignored, and in the end, the clock would not run correctly. When the clock owner asks us to perform a minor, non-guaranteed repair, the receipt the customer receives will reflect the lower level of work performed, that there is no guarantee, they will sign a form acknowledging the risk and they will pre-pay. The receipt for this clock listed that the clock had been overhauled and the company’s sticker was placed on the seat board next to their repair mark.