Before and After: Clock Dials

Clock Dial Restorations

Restore or not - Differing Opinions

Just like clock cases, there is often a debate as to whether a clock dial should be restored or left in its current worn or damaged state. As always, we do not try to make this decision for our customers, we simply give them information that allows them to make an informed decision. Generally speaking, a badly damaged dial is simply not very pleasant to look at. For most people, this is the main determining factor. How a restored dial effects the value of the clock varies based on the commonality or rarity of the clock. For most common antique clocks, the value of the clock is not high enough to make it a difficult decision. If you want the dial to look nice, restore it. if you like the old look of a dirty or damaged dial, leave it as is. The bottom line is, what will make you happy when you look up at the clock to see what time it is. If, however, you have a rare or very valuable clock, then leaving the original dial in its worn or damaged state may be preferrable. Most of the dials you will see pictured below, although from very nice clocks, are not worth hundreds of thousands of dollars. Some of them may have significant value but are not so rare that restoring the dial, seriously damages their antique value. for more common clocks, the change in value of a clock with a damaged dial may be the same as having a clock with a restored dial, making it a wash. For most of the owners of these clocks, they have no intention to re-sell their family heirloom, so they have no serious concern as to how it might or might not affect the value of the clock, they simply want to enjoy the clock and pass it down to future generations. The photos below simply offer our customers a chance to see the transformation from damaged to restored so they can make an informed decision as to whether to restore or not.

Important Note - Please Read

With the exception of reproduction paper dial replacements, we do not perform the dial restorations you will see below ourselves but send them out to professional, qualified dial restoration experts that we trust and have worked with successfully in the past. If you are working with us directly, we are happy to handle this process for you, but please do not ship us a dial to be restored without speaking to us first. It rarely makes sense for you to ship us a dial, only to have us ship it out to someone else. In those instances, it makes more sense for you to find a company that you can work with directly instead of using us as a middleman.

brass and silver dial restorations

Brass and Silver dials are made up of many individual pieces and therefore require a tremendous amount of labor to restore. The dial must be disassembled, the old lacquer stripped off, the brass polished and re-lacquered. The silver parts of a dial are actually made of brass but have a thin layer of silver on top. This thin silver layer is very fragile and any attempt at cleaning it will remove the silvering and expose the brass underneath. when this occurs all the old silvering must be removed so that only the brass is left. Then the piece is re-silvered and the numbers re-inked. Once all this is done, everything must be reassembled. If the dial has a moon dial, that is another project unto itself. The original, damaged moon dial is photographed, and a new dial is often hand painted to match the original as closely as possible.

English Elliott Tubular Bell Clock Dial

As just mentioned above, someone’s attempt at cleaning the silver parts of this dial resulted in all the silvering being inadvertently removed. To get an idea of the amount of work that goes into a restoration like this, the dial below contains 29 individual pieces.

Before

After

Another Similar Example from a Different Clock

Before

After

This dial is a bit different as the entire dial was silvered.

Before

After

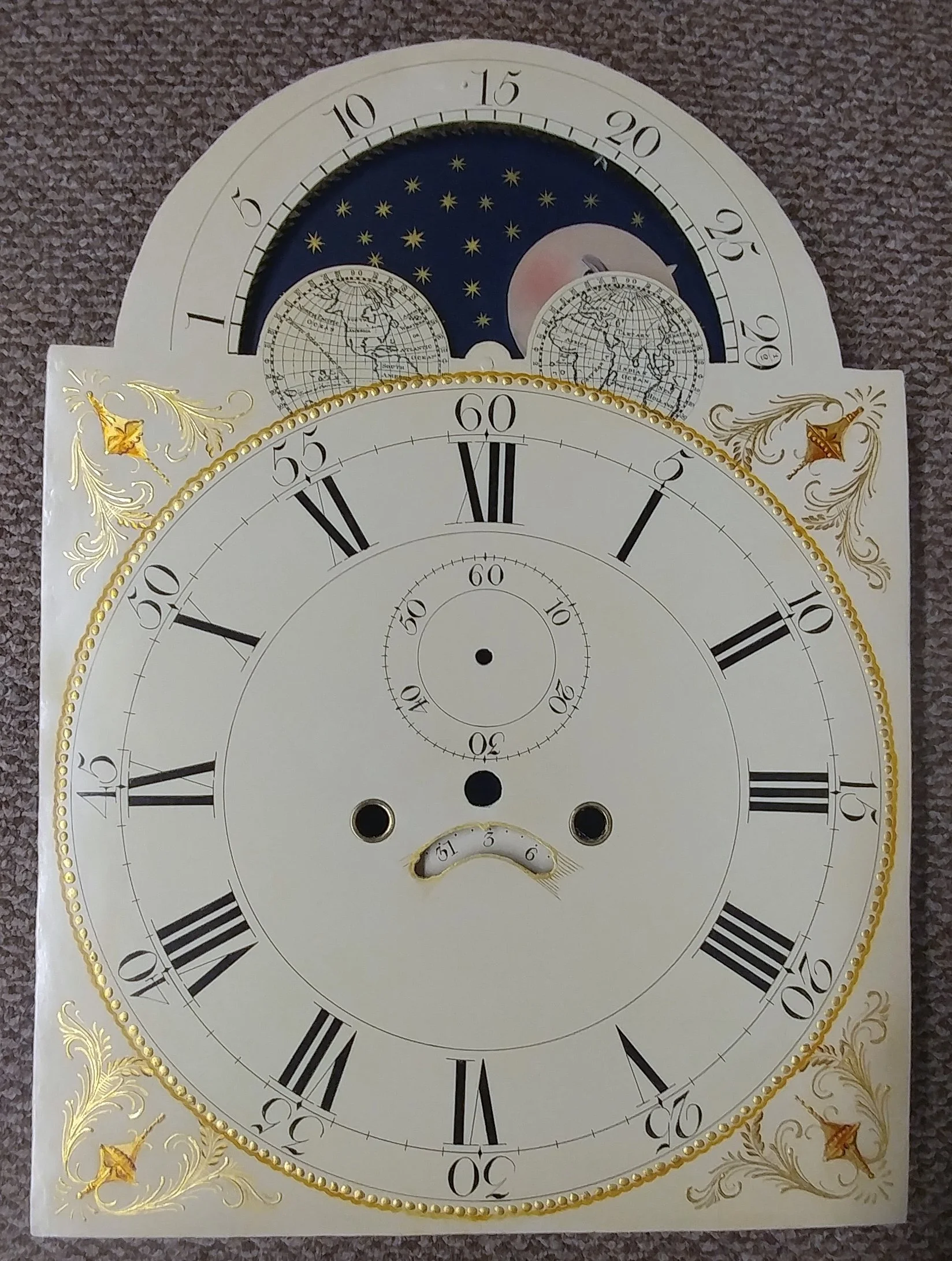

White dials From Antique Tall Case Clocks

A “White Dial” is the term used to describe dials that are most often just a single piece of steel, painted white and then embellished by hand painting various pictures and or decorations around the chapter ring that contains the numbers and minute markings. By comparing these dials to the ones above, you can see that these dials were far less labor intensive to make but equally pretty. For more information about white dials please see our “The Art of the White dial” page.

This dial did not need to be completed stripped and repainted. We had the dial cleaned and some of the embellishments touched up as well as the numbers re-inked.

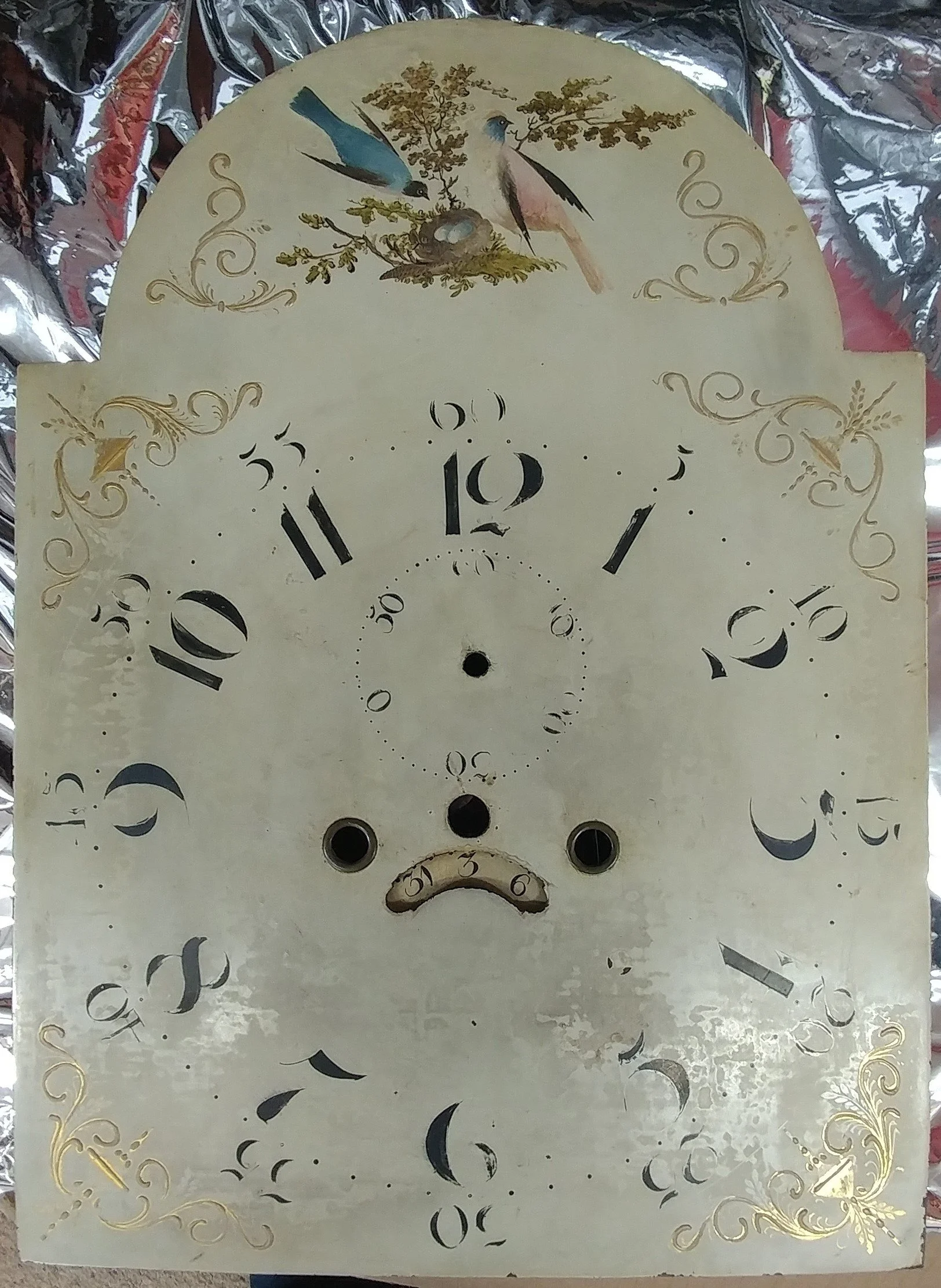

Before

After

In the example below, someone made a poor attempt at “touching up” the dial. This dial was photographed, completely stripped and then repainted to look like the original. A special wash was then applied to make the newly painted dial look “aged”.

Before

After

Like the example above, this dial was also poorly touched up. The gold corner decorations and the “hemispheres” under the moon dial had lost much of their fine detail. The moon dial was also stripped and repainted.

Before

After

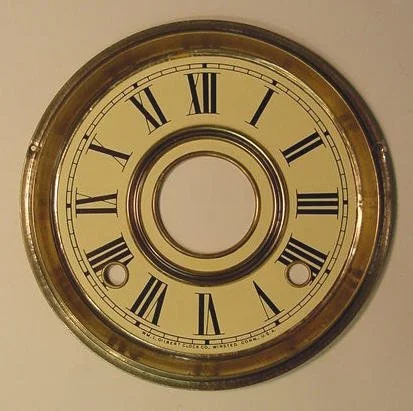

Antique American Paper dial replacements

Many American made clocks from very late 1800’s through the early 1900’s had paper dials glued to metal dial pans. Paper dials were inexpensive to produce and allowed the early American manufacturers to make the clocks as affordable as possible to the widest range of potential clock buyers. Paper dials of course were not very durable and often became very dirty or the paper itself got rubbed off from continuous handling. As these dials aged it was determined that there was a need for paper dial replacements. The early replacements that were made (most likely in the 1950’s and 60’s) were not “reproductions” at all but just generic, plain dials, often printed on glossy, very white paper. These dials did not quite look right on the old clocks and because they were generic, did not have the clock manufacturer’s name on them, like many of the originals would have had. In addition, many of these early replacement dials were installed very poorly.

Now, quality reproductions of the original dials are available, printed on white or off-white nonglossy paper. When installed properly, these dials look more natural than the early generic ones.

This is the type of dial work that we can do ourselves. The following examples were all done “in-house”. First, we strip the old dial from the dial pan, clean and polish the dial pan, cut the proper reproduction dial to fit and glue it to the original dial pan.

Examples of Paper dial Replacements

Before

After