The Art Of Clock Repair

Painting above by Jim Andrew

For some clockmakers, getting the clock to function is their only concern. (For examples of this mind set, see our “Hall of Shame” page.) For other clockmakers, like Michael, there is an attempt to perform repairs, in not only the most durable and functional fashion, but also, in an artful manner. Whether it is drawing, painting, building model kits or repairing clocks, Michael's personality leans toward detail, art and taking great pride in everything he does. For examples of some of his hobbies go to “Michael's Hobbies” page. Below are some examples of work that he has performed that showcase this concept.

Unusual and Extraordinary Repairs

The “Art” of Clock Repair

This page is designed to offer a glimpse into the more difficult and time-consuming aspects of clock repair that the general public rarely sees.

Most of what a clock repair person does on a daily basis is quite routine. Everything we need is there, we just need to rebuild it, clean it, oil it, or adjust it. Occasionally we run into a situation where a part is so badly damaged that it must be completely remade from raw materials, other times, it can be repaired using creative restorative principals. This is often necessary because we simply cannot obtain replacement parts for most antique clocks. Michael is not a machinist, although he surely has some machining skills. For this reason, he does not claim that everything shown here has reached the perfection that he strives for, but I think you will see that the work was done with much more accuracy and skill than the previous person’s work, which Michael is trying to repair.

The teeth on the various gears inside a clock are vulnerable to damage due to shock from dropping, mainsprings breaking or from misguided attempts at repair. Let’s look at a few examples of this type of work.

Teeth replacement

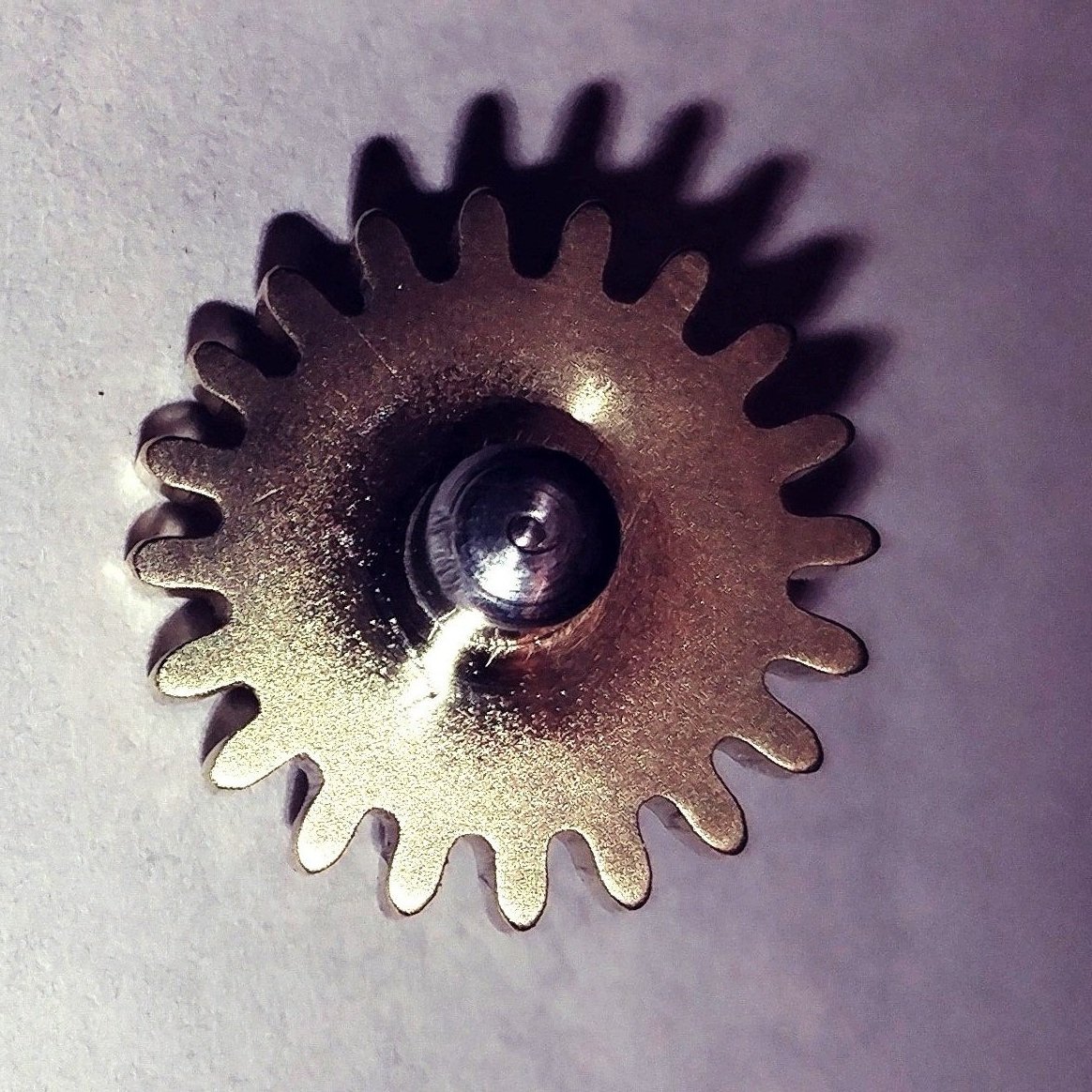

Escape Wheel

The teeth on escape wheels are more vulnerable to damage than most as the teeth are typically much finer and often sharper. On the left below, we see that someone has made a thin slit where the broken tooth tip was and replaced it with a thin sliver of steel, probably a piece of old mainspring. Steel is not the appropriate type of metal to use since the original material, brass, is much preferred. A steel tooth will do more damage to the part that it interacts with, a part called the pallets which are also made of steel. The photo on the right shows the repair done properly and with brass. A wider, neater slit was made, and a piece of brass sized to fit the gap was inserted, soldered in place and then filed to shape. The actual size of this escape wheel is about the size of a quarter. If this photo was the actual size, you likely would never notice that this wheel had ever been repaired.

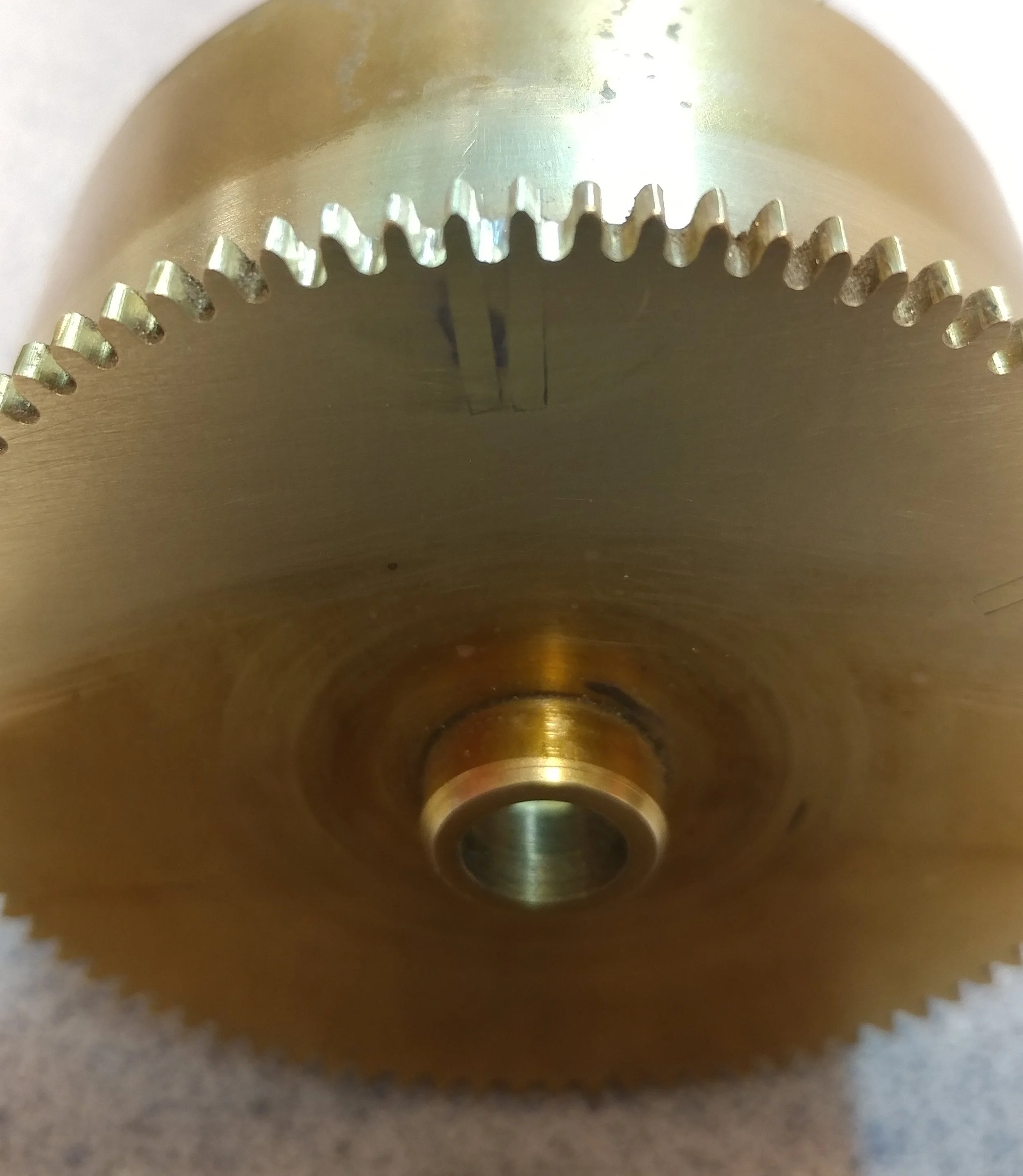

Winding wheel

This is an intermediate wheel used to aid in winding of the clocks’ mainspring. Sometimes, through abuse, these teeth will get bent or break off. The first photo shows rough slits made where the broken teeth used to be. The middle photo shows rough “plugs” inserted and then soldered in place. Notice we did not use “blobs” of solder, like you will see on the “Hall of Shame” page of our web site. The photo on the right shows the plugs filed to proper shape and then the wheel polished to remove any excess solder. You can still see a faint outline from the single tooth, but the two-tooth section is invisible even at this magnification. This winding wheel is about the size of a nickel.

Damaged Mainspring Barrel Teeth Repair

Slide Show

Replacing Teeth on an Hour Wheel attached to a Snail

This part of the clock, close to 200 years old, tells the clock how many times to strike on the hour. You can see that the brass piece on top actually looks like a snail shell, hence the term “snail”.

photo one shows the poorly repaired teeth visible by the solder near the top and bottom.

Photo two shows the bottom of the hour wheel where the poorly repaired teeth can be plainly seen. The snail had to removed in order to perform the repair.

Photo three shows the newly replaced teeth barely visible at the 12 and 5 position.

Photo Four shows the snail reattached and all the parts cleaned. You can barely see the repaired teeth at the bottom of the photo near the 6 position.

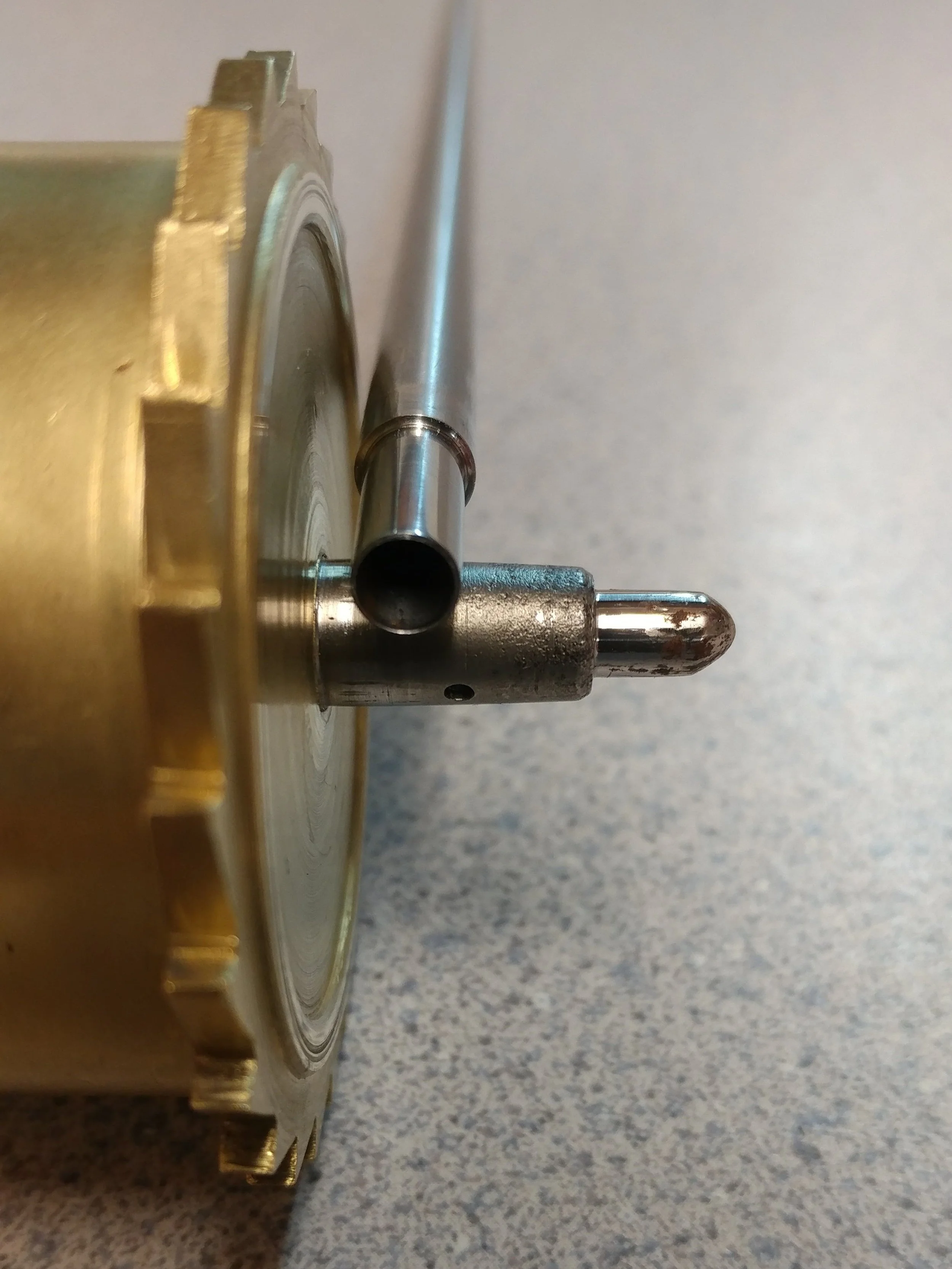

Making a New Snail Pipe

The part below was damaged when the clock movement was shipped to me for repair. You can’t order a part like this from a catalog, you either make it or repair it. I chose to repair it. The dimensions of the new pipe must match the dimensions of the old one in order for it to function correctly. it also must be mounted perfectly perpendicular to the bridge plate that sits under it.

Slide Show

Lever Repair

Clock movements contain many parts other than gears and wheels, levers being the most common. Levers, most often, are there to control the functions of chiming or striking. Although levers don’t typically wear in the same way that bearing holes wear, they often need adjusting and this often leads to damage when not done correctly. Below see some examples of repairing damaged levers as well as making entire levers from raw material.

Making a New Rack Tail

The slide show below shows the process of making a new “rack tail” for an antique bell striking tall case clock. This type of clock dates before 1870 and can go back as far as the early to mid 1700’s. The “rack” is the part of the clock that controls the number of strikes that will occur on the hour. The rack tail is thin and vulnerable and can be abused, unknowingly, by the owner or by less than adequately skilled clockmakers. In this instance, the rack tail, although damaged and weak, was of the proper size and shape so I did not have to guess at its design like I often do in other situations.

Making a New Rack Tail

Slide Show

Another Example of Making a New Rack Tail

Making a Rack Tail without knowing where the Rack Tail pin should be located.

There are several adjustments that are critical for proper strike function: the angle between the steel rack and the brass rack tail, the position of the rack tail pin that falls on the snail and the positioning of the snail itself over the hand shaft. If any of these are wrong, it will not work correctly. All of the rack repair examples are from very old antique floor clock movements from the late 1700’s thru the late 1800’s. These clocks have a fairly strong spring that throws the rack down a few minutes before the hour. All of this hard falling over the centuries, along with improper setting of the hands and poor attempts at repair, mean that this part is often badly damaged or broken. The following slide show shows how the position of the rack tail pin is determined when the original part is missing or badly damaged.

Important Note

In the example of the work below, I am willing to admit my mistake of using brass when I should have used steel to make the replacement piece at top left. You should always use material that is like the piece you are repairing. At the time, about ten years ago, I mistakenly chose brass knowing it would be easier to cut and file. This has not affected the strength or function of the repair since this part does not receive wear. The replaced brass part is there to hold the pin that causes the strike sequence to stop. This part, I did make from steel, because it needs to be durable against the force of the gathering pallet that lands there to stop the strike sequence.

Determining the position of the rack tail pin

Replacing a Missing Count wheel Lever

This antique bell striking tall-case clock came to me missing an important lever, the one that controls the strike function. After doing some research, I found a photo of a similar clock to get an idea of the shape of the lever. View the slide show below to see how I made the new lever.

Slide Show

Repairing a poorly repaired Bell Striker Lever

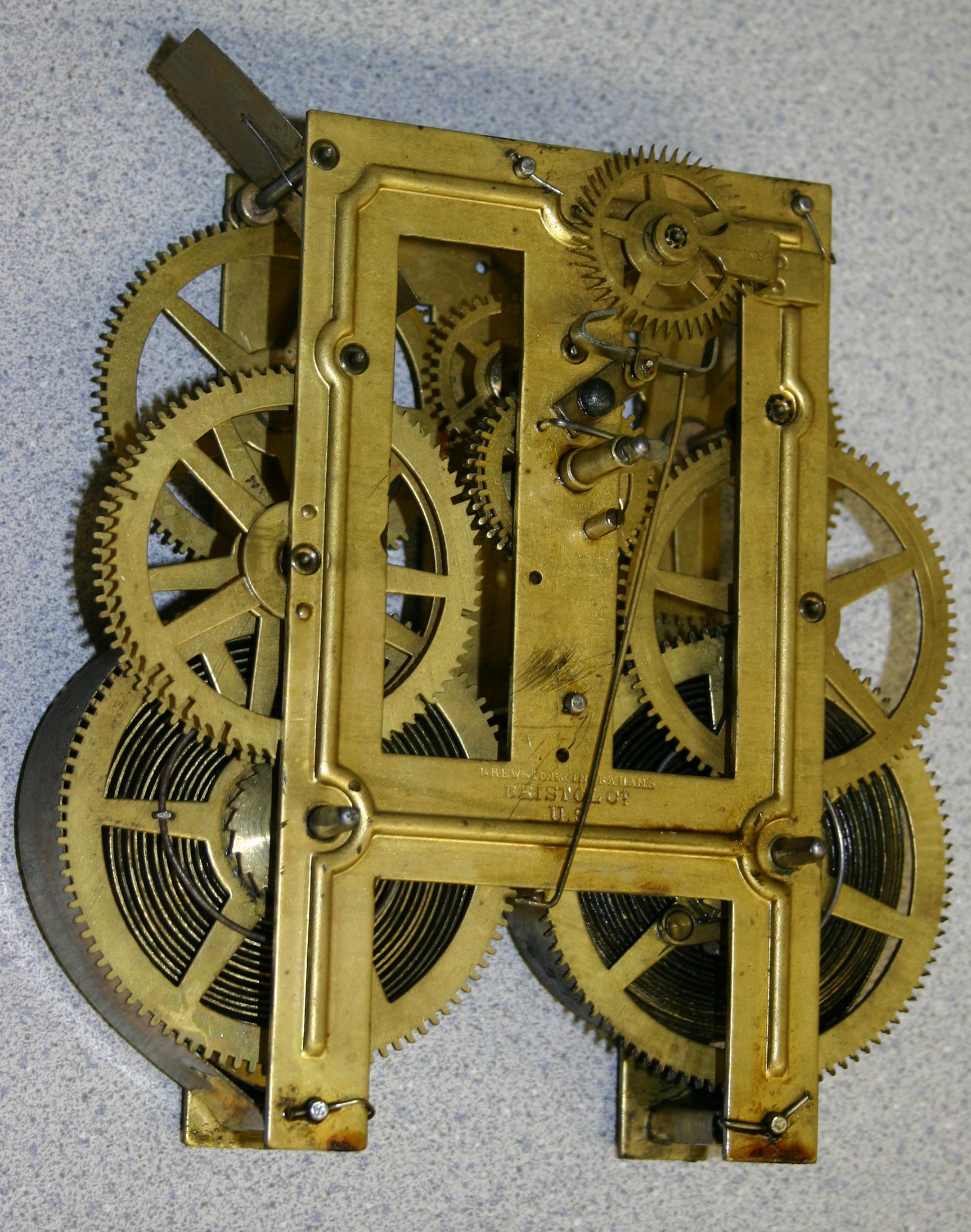

Making New Levers for an Antique Striking Mantle Clock

I received the clock pictured below with no levers to control the strike function. I was extremely fortunate to find someone that had this clock and could send me the levers to copy. Below right, are the new levers in which each component piece was made from raw material. The new levers are the shiny ones on the outside and the rusty ones in the middle are what I copied them from. The movement on the left is a Brewster and Ingraham clock with brass mainsprings.

Gathering Pallet Repair

Gathering pallets are parts of a clock that control the strike or chime function when a rack and snail is present. Below is a unique form of gathering pallet. The clock was about 100 years old and through age and fatigue the brass sleeve simply broke leaving the gathering pallet to spin freely on its arbor.

Repairing a Broken Gathering Pallet

Slide Show

Repairing a Broken Chime Control Cam

Slide Show

Repairing a POORLY Formed Pivot

I restored an antique bell striking tall case clock movement a number of years ago that had a pivot on one of the mainwheels, that no matter how much I filed and polished it, I kept exposing impurities and empty pockets of air in the steel. After consulting with someone very knowledgeable about metallurgy and centuries old blacksmithing techniques, I learned that when making steel, blacksmiths would often place “things” into the “mix” that would affect the hardness of the steel. According to some “ancient recipes”, sometimes a rat would be thrown into the molten steel. Strangely, there was some element in the dead rat that would have an effect on the quality of the steel. Apparently, these pits were caused by some “substance” in the steel other than a metal. Instead of replacing this very large pivot I placed a “sleeve” over top of it instead. See how I did it below.

“Sleeving” a Bad Pivot

Slide Show

Repairing a Dial Post

This is the backside of a dial for an antique bell striking tall case clock. One of the post tips that go through a hole in the movement broke off where the hole was drilled to receive the taper pin that keeps the post from pulling out. The first photo shows the broken post and the second shows the repaired post. it was necessary to flatten the broken post where the diameter is reduced for the tip, center drill the post and then insert a properly shaped plug into the drilled hole. All of the machined dimensions were precise and tight enough that I could tap the post into the hole and finish it off with a bit of low temperature solder.

Making a New Pulley Saddle

A pulley saddle is the part that the weight hangs from and also holds the pulley that rotates as the clock runs down. The badly worn pulley saddle in the slide show below came to me with a set of weights and a pendulum from a 100-plus year-old, high-quality tubular bell tall case clock. The owner wanted me to refinish the weights, the pendulum and the pulleys. upon examination of one of the pulleys, the one that held up a 40-pound weight, I discovered that the pulley was worn so badly it was about to wear right through to the edge, which would eventually have resulted in a horrible noise and great damage when the weight hit the floor of the clock. Although we could obtain a generic replacement pulley and saddle, the owner wanted it to match the other two and also wanted to retain the look of the originals. I then set about the task of making a new one exactly like the original.

Making a New Pulley Saddle

Slide Show